ATXONDO

EUROPE

Incorporated into GIS in 2015 through ACE Group’s acquisition.

A facility specialized in production of Brackets, maintaining leadership in European market.

Incorporated into GIS in 2015 through ACE Group’s acquisition.

A facility specialized in production of Brackets, maintaining leadership in European market.

Cast in vertical molding of Ductile Iron

220

2 DISA lines

51,000 k annual tons

Brakes: Brackets

• IATF-16949:2016

• ISO 9001

• ISO 14001

• ISO 45001

• EMAS

• TÜV Declaration

• Natural Environment Declaration

• Environmental Policy (MA)

• Occupational health and safety policy (OHS)

1968

Co-Design, Prototipes, Initial PPAP

• IATF-16949:2016

• ISO 9001:9001

• ISO14001

• CTPAT

• Quality Policy

2010

Acquired by INFUN and relocated in 1996. First facility of the group and where the Headquarters are stablished.

Incorporated into GIS in 2016 through INFUN’s acquisition.

| * DRAXTON EUROPE & ASIA SL has developed the project “Desarrollo de un sistema tomográfico de elevada precisión que permita reducir la fracción bruta” (Development of a high-precision tomographic system to reduce the gross scrap rate), aimed at incorporating advanced inspection technology to enhance production process quality and optimize performance through more accurate detection of defects and deviations. |

| * The project’s total investment amounts to €561,980.00, of which €140,994.00 has been co-financed by the European Union through the European Regional Development Fund (ERDF). |

| * Thanks to this support, a high-precision tomographic system has been implemented, helping to increase the competitiveness, efficiency, and reliability of production processes, delivering annual energy savings of 1,508.510 MWh as a result of the initiative. |

Cast in vertical molding in Ductile, Vermicular and Silicon-Molybdenum material grades.

110

2 DISA lines

40,000 annual tons

Powertrain & Chassis: Clutch Plates, Pressure Plates, Crankshafts, Suspension Arms, Connecting Rods, Mounts, Brackets, EGR Valves, Bearing Caps and Knuckles.

• IATF 16949:2016

• ISO 14001

• ISO 50001

• ISO 9001

• QS9000

• OHSAS ISO 18001

• Occupational health and safety policy (OHS)

• Environmental and Energy Efficiency Policy

1948

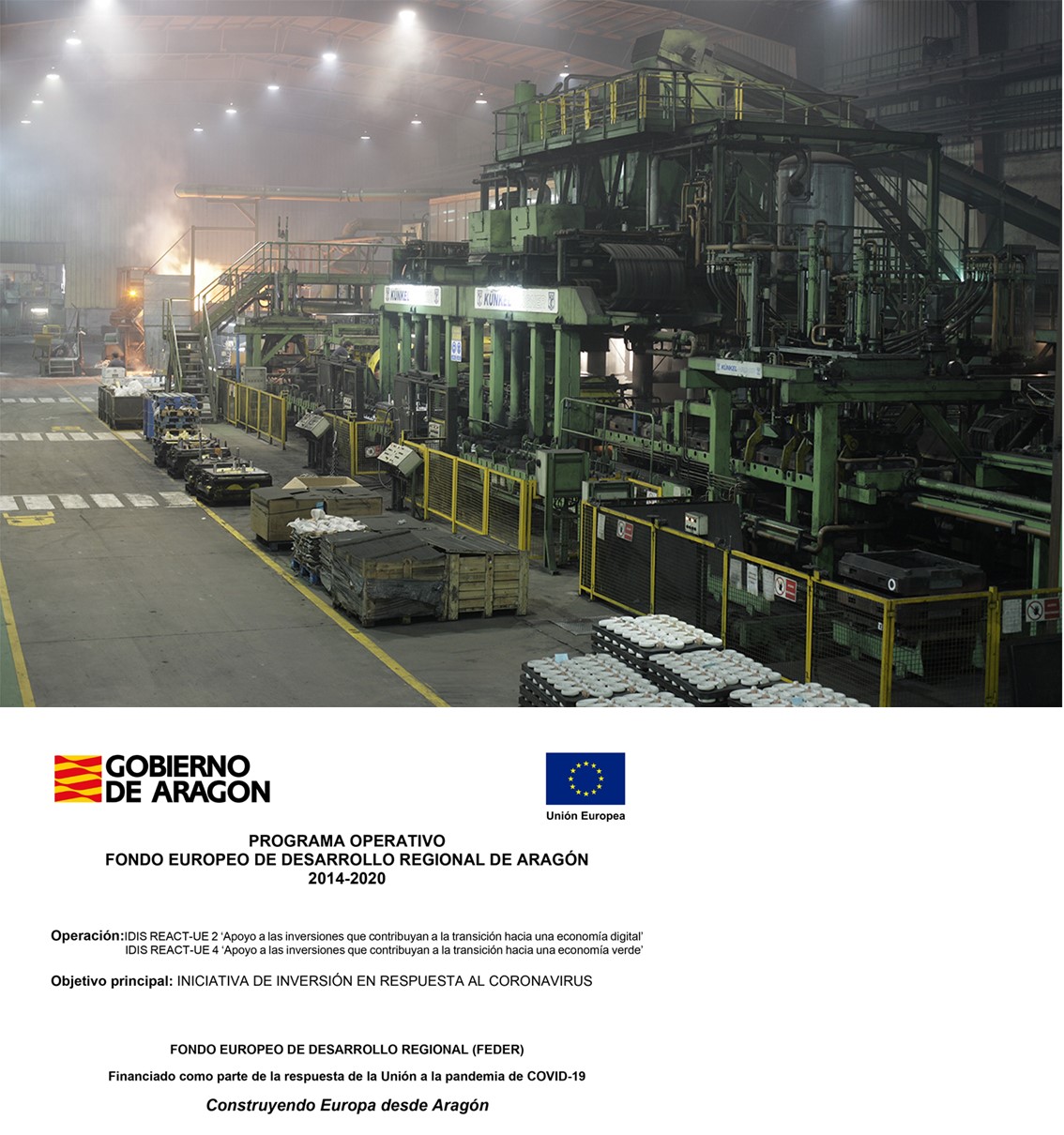

Founded with a Kunkel Wagner line for horizontal molding and in 1997 the DISA line was installed for vertical molding.

Incorporated into GIS in 2016 through INFUN’s acquisition.

| * Project Description: Development of a new methodology of tooling design that allows the use of conventional dimensions tooling’s for the development of large dimension parts with high pouring requirements. * This project has been financed by the Teruel Investment Fund. Subsidy € 208,786.34. Project Code: 50 / 088-006. |

| * Project Description: Action to improve energy efficiency through the development of a mold filling control system with a vision camera for the reduction of the gross fraction that allows energy saving to carry out the melting of the metal. |

| * Financied by: Instituto para la Diversificación y Ahorro de Energía - FEDER. Total Investment: 187.750,00 €. Subsidy: 55.998,95 €. Estimated energy salving 75.59 toe per year. |

| * Project Description: Instalation of a plant for the mechanical regeneration of casting sandcores. Project Code Nr EC-06-2023. Subsidy: 53.462,50 €. * Project Description: Investigation of a new Balance Axle Frame for usage on Industrial & Transport Vehicles through advanced simulations. Project Code Nr 23/053-008. Subsidy: 73.668,29€. |

Cast in vertical & horizontal molding of Gray & Ductile Iron

240

1 DISA line 1 Kunkel Wagner line

70,000 annual tons

Powertrain & Chassis, Transmission: Crankshafts, Differential Cases, Supports, Control Arms, Flywheels, Bearing Caps.

• IATF 16949:2016

• ISO 14001

• ISO 9001

• ISO 50001

• QS9000

• ISO 45.001

• Environmental and Energy Policy

• Occupational health and safety policy (OHS)

1993

Trying to advance in the industry’s supply chain, the process of machining and assembly was strategic to INFUN.

Incorporated into GIS in 2016 through INFUN’s acquisition.

Machining and Assembly (Iron)

70

34 CNC: Okuma, Enshu, Heller, Brother & Haas

3.2 million units

Powertrain & Chassis: Mounts, Brackets, Suspension Arms, Diff Housings & EGR Valves.

• IATF 16949:2016

• ISO 14001

• ISO 9001

• QS9000

• OHSAS ISO 18001.

• Environmental Policy

2005